The IFR 50 is a UV flame detector specifically designed for difficult conditions often encountered in industrial single flame combustion applications. The IFR 50 can be connected directly to the ionization or LDR input of the control box. The UV sensor ensures that the flame detector does not react to background radiation from hot refractory or any other source of infrared light.

The UV flame monitor must be switched off once a day. For safety reasons and technical regulations, it must be ensured that the burner is switched off at least once every 24 hours.

The IFR 50 UV flame detector is designed to meet the requirements of UL 372-2, CSA C22.2 and EN 298. The internal increase of the UV tube voltage by 15% during the start-up phase ensures the safety requirements for testing the UV tube until ignition. The UV flame detector IFR 50 must be switched off for more than 5 seconds before burner operation can be resumed.

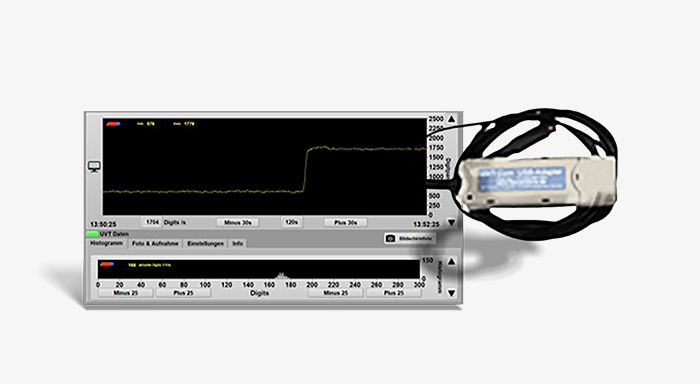

The UV flame detector is equipped with an optical interface that visibly displays the intensity of the flame signal. A simple diagnosis of the flame intensity is possible directly at the furnace boiler. The optical interface can also be visualized with the UVT-COM module of the BST-COM software.